01 August 2018

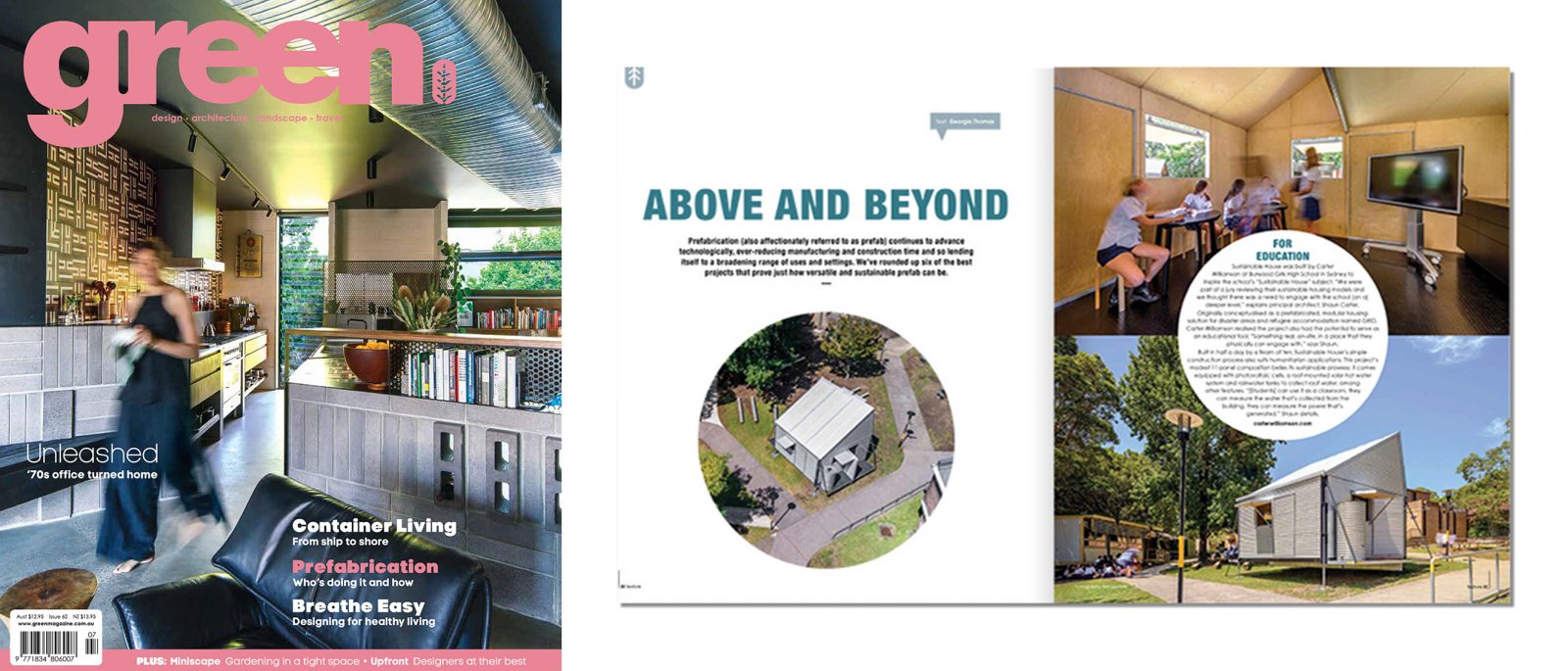

Above and Beyond

Article by Georgia Thomas for Green Magazine, Issue 62.

Prefabrication (also affectionately referred to as prefab) continues to advance technologically, ever-reducing manufacturing and construction time, and lending itself to a broadening range of uses and settings. Green Magazine has rounded up some of the best projects that prove just how versatile and sustainable prefab can be.

For Education

Sustainable House was built by Carter Williamson at Burwood Girls High School in Sydney to inspire the school’s “Sustainable Home” subject. “We were part of a jury reviewing their sustainable housing models and we thought there was a need to engage with the school [on a] deeper level”, explains principal architect, Shaun Carter.

Originally conceptualised as a prefabricated, modular housing solution for disaster areas and refugee accommodation named GRID, Carter Williamson realised the project also had the potential to serve as an educational tool. “Something real, on-site, in a place that they physically can engage with”, says Shaun.

Images: ‘Sustainable House’ by Carter Williamson

Built in half a day by a team of ten, Sustainable House’s simple construction process also suits humanitarian applications. This project’s modest 11-panel composition belies its sustainable prowess; it comes equipped with photovoltaic cells, a roof-mounted solar hot water system and rainwater tanks to collect roof water, among other features. “[Students] can use it as a classroom, they can measure the water that’s collected from the building, they can measure the power that’s generated”, Shaun details.

For Urban Living

Prefabrication proposes inventive solutions to site restrictions, offering speed and convenience beyond the realm of traditional building methods. Bill McCorkell of Archiblox agrees, saying: “When I started, I thought prefab, by its nature, has to be limited – but as I go on, I find that is not the case. It’s only limited by our creativity”.

In our facility in Laverton, we have control over all stages of the construction process. “Constructing in our facilities means we have the ability to manage the day-to-day trades (tilers, plasterers, etc.) who work on our homes so much more easily, and we can ensure quality work”, says Bill. Our Richmond Extension project is demonstrative of our detail-oriented philosophy.

Images: ‘Richmond House’ by Archiblox

The project consisted of three modules, which were transported and craned onto the narrow site with an existing Edwardian home. The straightforward nature of the prefab construction process meant that the extension was completed expeditiously. With a narrow street, neighbouring properties to be mindful of, and the clients having two children under 5 – prefab was just the right fit.

Archiblox has achieved a seamless, sophisticated addition to the existing home which also showcases prefab’s aesthetic versatility. “Prefab is not all about square boxes and conformity towards transport regulations and rules. Prefab is as flexible as your own imagination”, Bill notes.

For Community

The IMBY (In My Back Yard) Kit was created by Adriano Pupilli Architects as a response to Nimbyism – an abbreviation for “not in my backyard” that referenced discontent surrounding the development of high-rise and large-scale buildings in suburbia. IMBY Kit is designed to promote sustainable, incremental urban growth and empower neighbourhood inhabitants in the process.

Images: ‘IMBY Kit’ by IMBY

The kits are available in 5 models of varying sizes. So far, one has been built by Adriano along with colleagues Matt Ryall and Ben Muir. This IMBY is clad with charred western red cedar weatherboards, which Adriano reveals were achieved after “19 Hours with a blow torch and a bunch of LPG bottles! Good winter activity”. IMBY’s modular structural frame means that the kits can be extended, and they’re made up of interlocking mortise and tenon joints.

Sustainability is articulated here in maximising use of materials and minimising costs and waste. Machine efficiency manages repetitive tasks and by cleverly “nesting” multiple parts on a 1200 x 2400 standard building sheet (the sustainably-grown plywood) the most is made of the material. Adriano sees this project as a marriage of past and present design approaches, saying “IMBY encapsulates the simplicity of ancient woodworking techniques with the efficiency and sustainability of digital fabrication and renewable resources”.

For Retreat

Retreat in Finca Aguy by MAPA Architects is located in Pueblo Eden, Uruguay. This 115-square-metre project was designed to make the most of the surrounding landscape and the site’s scenic position on the edge of an olive field – a goal that its openable facade certainly achieves.

Images: ‘Finca Aguy’ by MAPA Architects

The structure was manufactured in a factory near Montevideo and was then transported 200 kilometres to the site. MAPA Architects summarise the project thus: “[The] perfect combination of industry and landscape: new kinds of landscapes deserve new ways of living.”

Prefab was selected for this project because of its precision and reduced environmental impact. In such a natural, undulating landscape, MAPA Architects understood that their architectural response had to be restrained and uncomplicated – the speed and ease of construction, along with waste minimisation offered by prefab proved the perfect solution.

We love sharing all the new and exciting things happening at Archiblox, so make sure you’re following us on

Instagram ,

Facebook

and

Twitter,

or signed up to our

monthly newsletter, to ensure you don’t miss a thing.